Introducing the PlasmaPOD™ Family of tools

Earlier this year Plasma-Therm, our parent company acquired JLS Design Ltd in the United Kingdom, and with that came the PlasmaPOD™!

These tools are small, compact table-top systems that are specifically designed for space-constrained University labs that are running Material Science courses, R&D departments of small to midscale device manufacturers who want to keep the cost of development under control, and small Failure Analysis departments where space and price are purchase constraints.

We have introduced a NEW customer journey for you to explore that enables you to purchase these amazing little tools directly from us via our brand new e-commerce facility.

We have the following preconfigured toolsets available;

- Reactive Ion Etch (RIE)

- Plasma-Enhanced Chemical Vapor Deposition (PECVD)

- Sputter Deposition

- 4 variations

- Barrel Etch

- 2 variations

We are looking forward to supporting YOUR needs with these excellent tools!

Barrel Etch

- Choice of 300W or 600W RF Generator with auto-matching

- Stainless Steel chamber with Aluminum Faraday Cage assembly

- 2 gas lines (inc MFCs)

- Internal PLC control system

- Touch-screen interface

- Capacitance manometer for pressure measurement

- Automatic closed-loop pressure control

- All controls are within the frame to minimize the footprint

- Built-in process recipe control and data logging

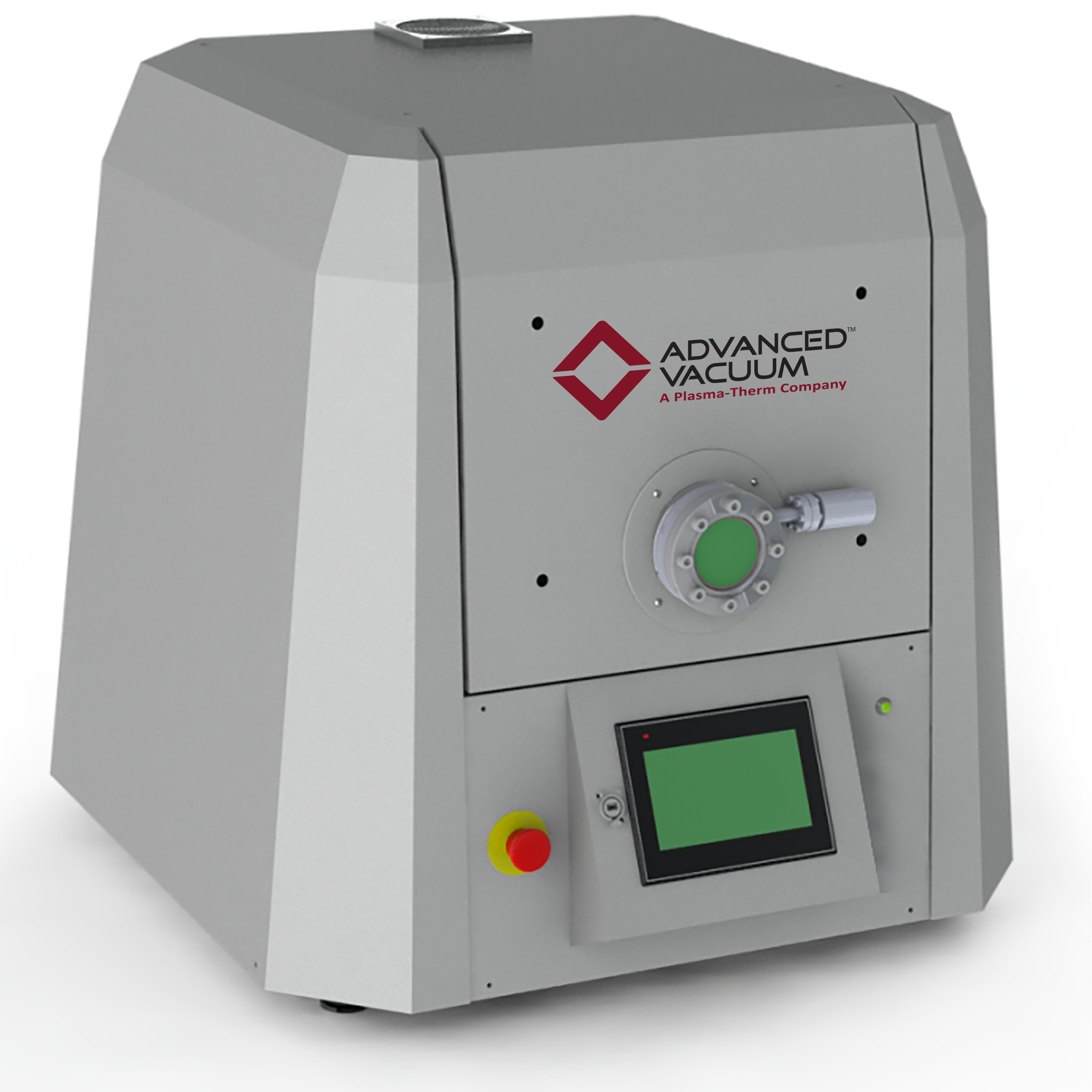

Sputter Deposition

- 300W RF Generator with auto-matching

- Stainless Steel chamber with internal shields

- 160mm electrode with rotation (optional water cooling)

- 2 gas lines (inc. MFCs)

- 3 configurations of Magnetrons plus fittings are available

- Internal PLC control system

- Touch-screen interface

- Automatic closed-loop pressure control

- Close-coupled Turbo (requires backing pump)

- All control within the frame to minimize the footprint

- Built-in process recipe control and data logging

PECVD

- 300W RF Generator with auto-matching

- Aluminium chamber with water cooling

- 240mm Heated electrode manufactured in stainless steel

- Internal PLC control system

- Touch-screen interface

- Capacitance manometer for pressure measurement

- Automatic closed-loop pressure control

- All control within the frame to minimize the footprint

- Built in process recipe control and data logging

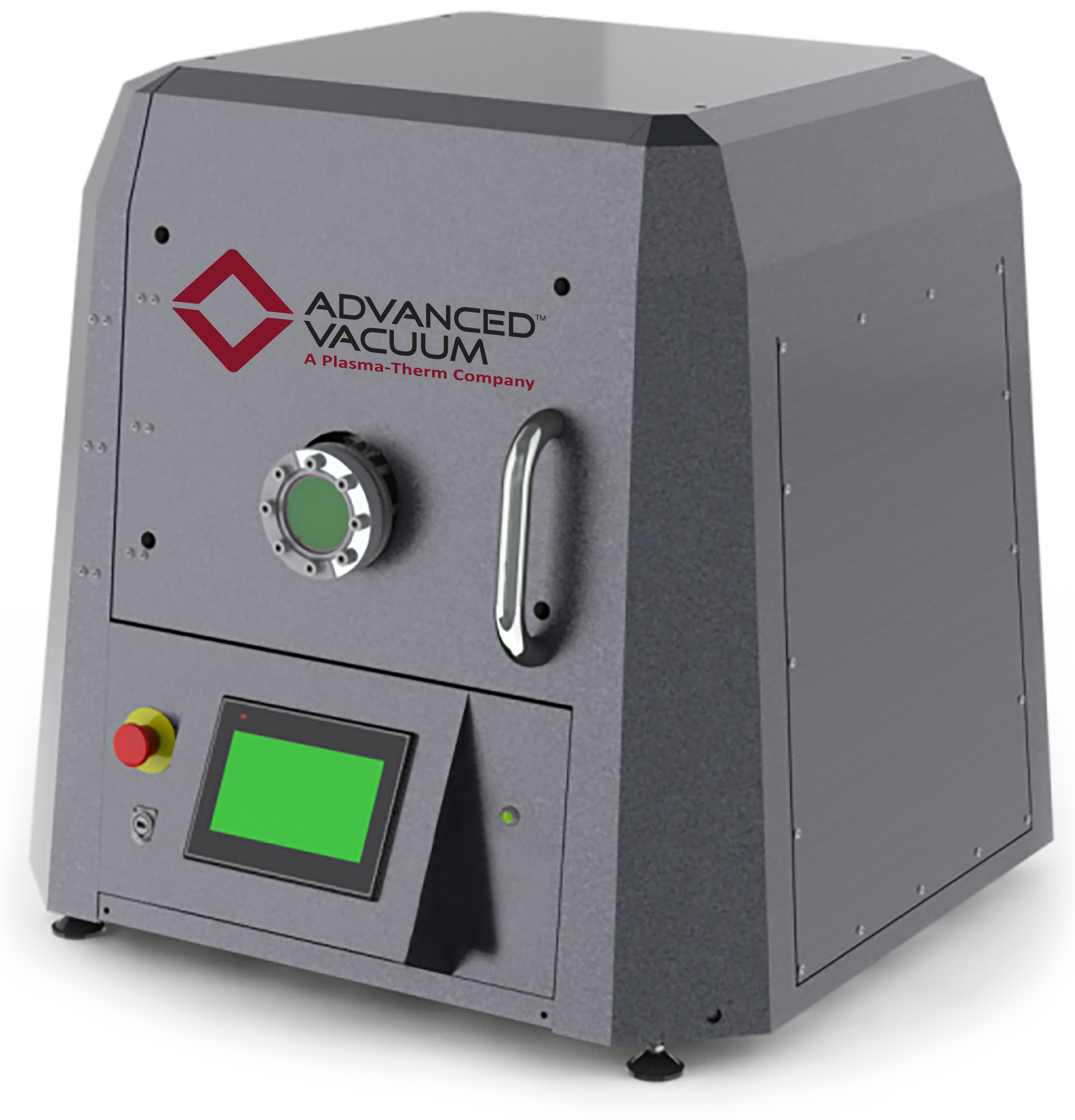

RIE

- 300W RF Generator with auto-matching

- Aluminum chamber

- 125mm electrode; water-cooled

- Internal PLC control system

- Touch-screen interface

- Capacitance manometer gauge for pressure measurement

- Automatic closed loop pressure control

- Close-coupled turbo

- All control within the frame to minimize the footprint

- Built-in process recipe control and data logging